With a lot of discussion recently about the use of straight wall wads in tapered wall hulls, and tapered wall wads in straight wall hulls, I was wondering if a study had been performed about the actual differences in performance of the actual straight wall vs tapered wall wads in the trip down the barrel. My first thought would be that the larger diameter straight wall wads would seal better against the barrel and produce a higher velocity out the end of the barrel than the smaller diameter tapered wall wads. Or maybe it doesn't make any difference as both of them are flexible enough to expand to the barrel and maintain the pressure of the burning and expanding gasses behind them? And still stay centered in the barrel? :?:

mountain4don

Straight wall vs tapered wall wads down the barrel?

mountain4don

Discussion starter

348 posts

·

Joined 2012

- Add to quote Only show this user

With a lot of discussion recently about the use of straight wall wads in tapered wall hulls, and tapered wall wads in straight wall hulls, I was wondering if a study had been performed about the actual differences in performance of the actual straight wall vs tapered wall wads in the trip down the barrel. My first thought would be that the larger diameter straight wall wads would seal better against the barrel and produce a higher velocity out the end of the barrel than the smaller diameter tapered wall wads. Or maybe it doesn't make any difference as both of them are flexible enough to expand to the barrel and maintain the pressure of the burning and expanding gasses behind them? And still stay centered in the barrel? :?:

13,847 posts

·

Joined 2009

Stan Baker made 12 gauge barrels with a bore diameter of .800. The wads always sealed.

6,399 posts

·

Joined 2009

The difference in diameter is maybe 10-20 thousandths. The base of the wad is not flat. It is cup shaped (technically called and obdurating cup.) When you apply a pressure in the 10,000 +/- PSI range to the bottom of this cup the relatively thin plastic lip on this cup will spread out as far as it needs to spread to make a seal. It does not take a lot of pressure to deform plastic 10-20 thousandths (certainly WAY under 10,000)

1,655 posts

·

Joined 2013

You are absolutely correct in your assumption concerning the sealing characteristics of just about any wad while traversing down the barrel. The are all pliable/soft enough to obturate to fit the barrel once entered. It's the micro-split second at ignition where the sealing/blooper issues are noticed in some applications, and likely far more noticeable in real cold weather than any other season. Some folks are anal about their cars and how they take care of them, then there are those of us that are anal about the shell we build, I'm prolly one of them. Most of us don't use a 1/2" bolt where a 3/4" is called for, I don't use a sloppy wad where a tighter one makes me feel better. What is it they say about shooting/reloading, it's 90% psychological, 10% physical, or sumpin like that? Whatever melts yer butter.mountain4don said:My first thought would be that the larger diameter straight wall wads would seal better against the barrel and produce a higher velocity out the end of the barrel than the smaller diameter tapered wall wads. Or maybe it doesn't make any difference as both of them are flexible enough to expand to the barrel and maintain the pressure of the burning and expanding gasses behind them? And still stay centered in the barrel? :?:

10,292 posts

·

Joined 2006

Obviously, it's better to have a tight fit or seal, at the wad/case juncture, BEFORE the charge is ignited. That's where a leak proof seal is really needed.

Once ignited, and you have 10,000 PSI behind the wad, it's going to expand instantly, out to whatever barrel size you have, be it .729, .740, or .800 . (12 gauge).

All this to say, "The only place the fit is critical is inside the hull". The rest will take care of it'self.

DLM

Once ignited, and you have 10,000 PSI behind the wad, it's going to expand instantly, out to whatever barrel size you have, be it .729, .740, or .800 . (12 gauge).

All this to say, "The only place the fit is critical is inside the hull". The rest will take care of it'self.

DLM

3,390 posts

·

Joined 2010

Except for DV-20. ;-)D L Marcum said:Obviously, it's better to have a tight fit or seal, at the wad/case juncture, BEFORE the charge is ignited. That's where a leak proof seal is really needed.

Once ignited, and you have 10,000 PSI behind the wad, it's going to expand instantly, out to whatever barrel size you have, be it .729, .740, or .800 . (12 gauge).

All this to say, "The only place the fit is critical is inside the hull". The rest will take care of it'self.

DLM

17,856 posts

·

Joined 2003

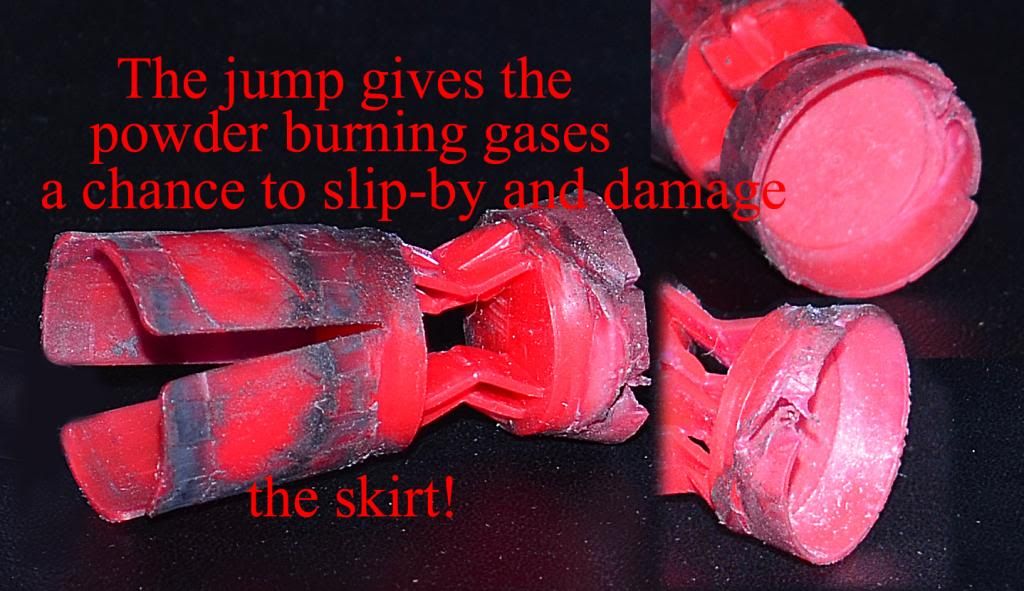

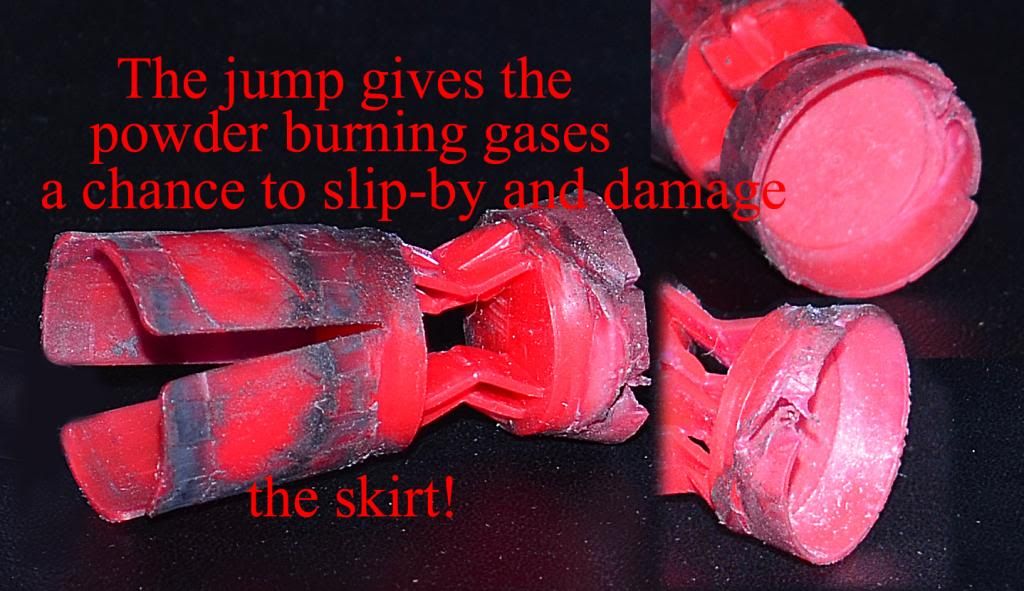

The DRV-20 seals just fine. The problem is it ruptures around the inside if the lip, gets cocked and when sealing tears parts of the lip off. It is because the cushion section is a poor design and or the lip is too short and or the plastic is the wrong formula.

I talked with Kevin at the NE state trap shoot and he told me he changed the plastic composition of the wad and that should fix it. He hasn't sent me any yet, but then again I haven't emailed him my address yet either. I should do that today and see what happens?

Sealing isn't the problem with that wad, it's the tipping, rupturing and tearing that's the problem.

BP

I talked with Kevin at the NE state trap shoot and he told me he changed the plastic composition of the wad and that should fix it. He hasn't sent me any yet, but then again I haven't emailed him my address yet either. I should do that today and see what happens?

Sealing isn't the problem with that wad, it's the tipping, rupturing and tearing that's the problem.

BP

10,292 posts

·

Joined 2006

The DRV-20 is a different problem. Has nothing to do with expansion of the powder cup.Jager1 said:Except for DV-20. ;-)D L Marcum said:Obviously, it's better to have a tight fit or seal, at the wad/case juncture, BEFORE the charge is ignited. That's where a leak proof seal is really needed.

Once ignited, and you have 10,000 PSI behind the wad, it's going to expand instantly, out to whatever barrel size you have, be it .729, .740, or .800 . (12 gauge).

All this to say, "The only place the fit is critical is inside the hull". The rest will take care of it'self.

DLM

It's problem is a weak and unevenly supporting cushion section, which when fired tends to let the powder cup tip up from lack of support on one side, then substantially letting the gas pressure bypass the powder cup. This is obvious when retrieving fired wads. Doesn't take a ballistic engineer to figure this out.

DLM

3,390 posts

·

Joined 2010

Yeah it tilts and isn't very resilient (be it material or dimension or both)...tearing the lip. I'd say that's a sealing problem, just a different mechanism.Burnt Powder said:The DRV-20 seals just fine. The problem is it ruptures around the inside if the lip, gets cocked and when sealing tears parts of the lip off. It is because the cushion section is a poor design and or the lip is too short and or the plastic is the wrong formula.

I talked with Kevin at the NE state trap shoot and he told me he changed the plastic composition of the wad and that should fix it. He hasn't sent me any yet, but then again I haven't emailed him my address yet either. I should do that today and see what happens?

Sealing isn't the problem with that wad, it's the tipping, rupturing and tearing that's the problem.

BP

Changing the material might help, but not addressing the cocking would still seem an issue.

Let us know how they shoot. The 20g market sadly needs more options.

3,390 posts

·

Joined 2010

Yeah, most wads you could darn near use again. Rumor has it it's even been done. The DRV's look more like they got caught in the garbage disposal.D L Marcum said:The DRV-20 is a different problem. Has nothing to do with expansion of the powder cup.Jager1 said:Except for DV-20. ;-)D L Marcum said:Obviously, it's better to have a tight fit or seal, at the wad/case juncture, BEFORE the charge is ignited. That's where a leak proof seal is really needed.

Once ignited, and you have 10,000 PSI behind the wad, it's going to expand instantly, out to whatever barrel size you have, be it .729, .740, or .800 . (12 gauge).

All this to say, "The only place the fit is critical is inside the hull". The rest will take care of it'self.

DLM

It's problem is a weak and unevenly supporting cushion section, which when fired tends to let the powder cup tip up from lack of support on one side, then substantially letting the gas pressure bypass the powder cup. This is obvious when retrieving fired wads. Doesn't take a ballistic engineer to figure this out.

DLM

3,390 posts

·

Joined 2010

RE: the OP.

Powder migration is the primary concern of straight vs. taper. Flake size and how much hadling the shell goes through between being loaded and fired would factors in how much effect it has.

That said, I've shot a lot of pheasant loads (which see lot of handling) in Activ hulls with Blue Dot and AA wads with no discernable issues....but maybe the pheasants just couldn't tell the difference that a chrono could. Of course they had a LOT of Blue Dot so there was some tolerance. Small grained powder like Longshot would seem to exacerbate the problem.

I'm not thoroughly convince sealing the length of the bore is a BIG issue. Seminole did a lot of testing with their gauge reducers (no hope of sealing down the bore) and saw ony a modest velocity reduction until it went to extremes (410 in 12g). That's not to say I welcome a lack of sealing.

IMHO the best designed straight hull wad is the Gualandi. Maybe art isn't needed, but it is a work of art.

Powder migration is the primary concern of straight vs. taper. Flake size and how much hadling the shell goes through between being loaded and fired would factors in how much effect it has.

That said, I've shot a lot of pheasant loads (which see lot of handling) in Activ hulls with Blue Dot and AA wads with no discernable issues....but maybe the pheasants just couldn't tell the difference that a chrono could. Of course they had a LOT of Blue Dot so there was some tolerance. Small grained powder like Longshot would seem to exacerbate the problem.

I'm not thoroughly convince sealing the length of the bore is a BIG issue. Seminole did a lot of testing with their gauge reducers (no hope of sealing down the bore) and saw ony a modest velocity reduction until it went to extremes (410 in 12g). That's not to say I welcome a lack of sealing.

IMHO the best designed straight hull wad is the Gualandi. Maybe art isn't needed, but it is a work of art.

403 posts

·

Joined 2011

My only concern is that the wad fits well enough to stop powder migration not only during handling but during loading as well. I remember a couple powders back when, 540 being one of them, that would allow powder grains to flow up around the wad if the fit was not good and tight. Thankfully we now have a much better selection of wads to choose from.

1,461 posts

·

Joined 2008

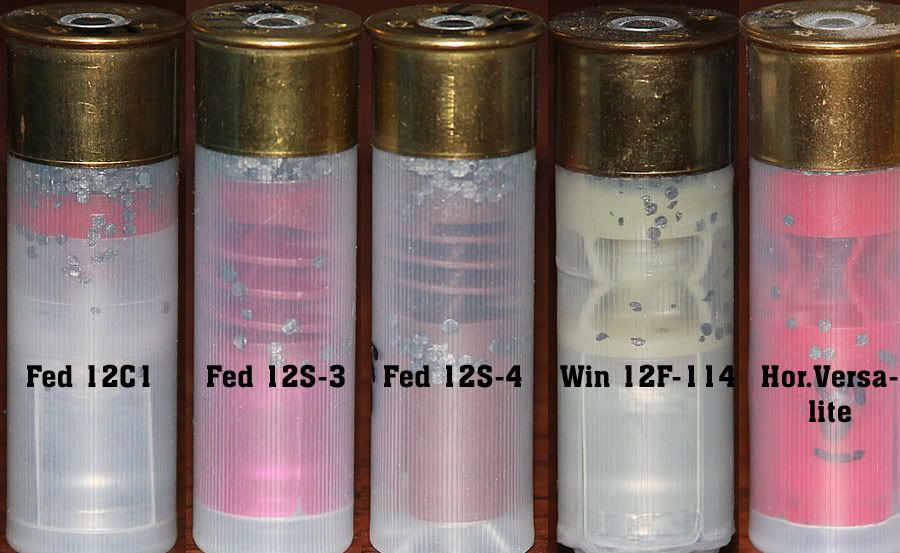

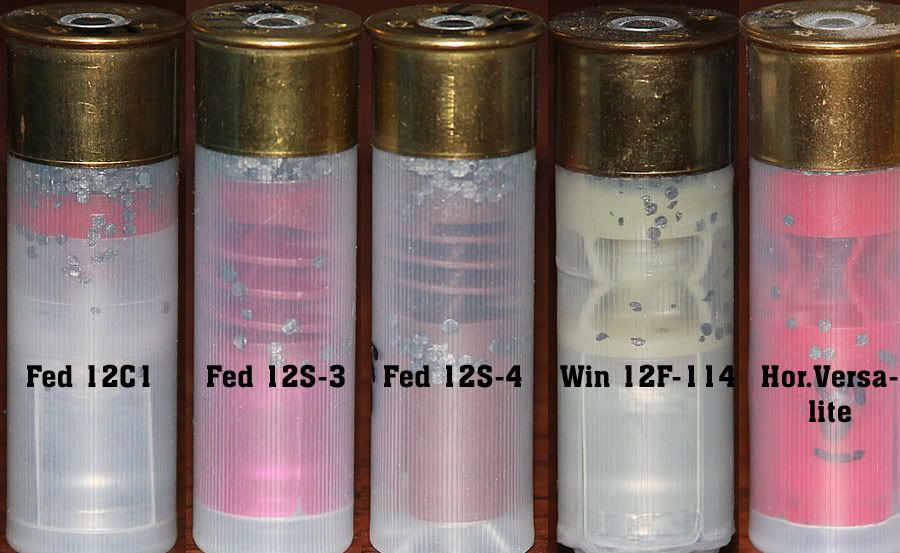

Greetings, I'll let the pictures do the talking:

![Image]()

[/URL]

Best regards,

Ajay

Super Blazing Sabots

BlazingSabots@Gmail.com

http://www.facebook.com/BlazingSabots?r ... B%2Furl%5D

http://slugshooting.accountsupport.com/ ... wforum.php

http://castboolits.gunloads.com/showthr ... ot!/page1

view...f=118&t=196961[/url]

viewtopic.php?f=118&t=196961

http://www.deeranddeerhunting.com/fo... ... B%2Furl%5D

http://www.go2gbo.com/forums/slug-gu...old-is-gold-!/

-Elite Group of Slug Shooter's

We all, who take slug loading seriously are a dedicated family, who have taken it upon ourselves to perfect our tech. We experiment to find better techniques and share our knowledge.

Location: New Jersey. USA / Frankfort, W.Germany / London, UK

-Elite Group of Slug Shooter's

We all, who take slug loading seriously are a dedicated family, who have taken it upon ourselves to perfect our tech. We experiment to find better techniques and share our knowledge.

Best regards,

Ajay

Super Blazing Sabots

BlazingSabots@Gmail.com

http://www.facebook.com/BlazingSabots?r ... B%2Furl%5D

http://slugshooting.accountsupport.com/ ... wforum.php

http://castboolits.gunloads.com/showthr ... ot!/page1

view...f=118&t=196961[/url]

viewtopic.php?f=118&t=196961

http://www.deeranddeerhunting.com/fo... ... B%2Furl%5D

http://www.go2gbo.com/forums/slug-gu...old-is-gold-!/

-Elite Group of Slug Shooter's

We all, who take slug loading seriously are a dedicated family, who have taken it upon ourselves to perfect our tech. We experiment to find better techniques and share our knowledge.

Location: New Jersey. USA / Frankfort, W.Germany / London, UK

-Elite Group of Slug Shooter's

We all, who take slug loading seriously are a dedicated family, who have taken it upon ourselves to perfect our tech. We experiment to find better techniques and share our knowledge.

403 posts

·

Joined 2011

Thanks for the pics, That is the point I was trying to make. And that is a flake powder, spherical powders are worse.

13,017 posts

·

Joined 2008

FYI, - the comment in this photo is incorrect ...VdoMemorie said:

You may not know about the situation with the yellow Downrange "DRV-20", but what you have illustrated in your photo has nothing to do with the powder cup (or powder past the lip), but is due to a geometry design problem with the crush section stilts exactly the same as the DRV-20:

As to the powder "migration" comments (in this thread and other recent related thread), something to consider is the definition that folks are attaching to that word.

"migration" (to me) means powder that "migrates", or gets by the gas seal on it's own, - induced by vibration.

The powder past seal shown here in this thread (and in that other thread) is not due to "migration" as I define it, but rather powder that got past the seal on wad insertion. It's a combination of the lack of an interference fit (i.e. "scraping" action), powder sticking to the hull due to static electricity, and the small air blast of trapped air just as the wad comes to rest on the powder.

To "test" for (true) powder migration, you'd have to tumble them in a tumbler, or do careful/controlled test of dropped loaded shells on a concrete floor (all of which I've done).

Only to come to the conclusion that, with flake powder in a compressed wad application, that there is a flake "interlocking" property going on that prevents flakes of flake powder from getting past the seal once the hull is loaded with a compressed wad.

Ball powders are a different story.

The effects of powder flakes not captured under the gas seal are indeed measurable with a chrono, but there are two metrics that are manifested. One: "average" reduction in MV, and two: "consistency" in terms of EV & SD.

Also in my testing, I have found that things are pretty repeatable, and as long as the amount of powder not captured under the cup is consistent from shell to shell, then the performance "consistency" will be minimal. i.e., if each shell has the same .1-.2 grains not captured under the cup, it will have minimal little affect on the performance consistency figures (EV & SD), and will only affect MV (lowering it by ~20-30 fps).

334 posts

·

Joined 2009

I just love to see that 3 foot flame come out the with the lead when the wrong wad is used.

17,856 posts

·

Joined 2003

Indeed, Republican is spot on in my experience. That wad design leaves a lot to be desired, especially in the 20 ga which I have done extensive testing with.

I have a hard time believing there is any 3' flame coming out of the barrel because of a tapered hull wad in a straight wall hull. If it's dark out and a flame blows out of the barrel it's going to regardless of the wad. If you can tell whether the flame is before or after the shot leaves the barrel you are a physical phenomenon!

BP

I have a hard time believing there is any 3' flame coming out of the barrel because of a tapered hull wad in a straight wall hull. If it's dark out and a flame blows out of the barrel it's going to regardless of the wad. If you can tell whether the flame is before or after the shot leaves the barrel you are a physical phenomenon!

BP

755 posts

·

Joined 2013

http://www.gaugemate.com/info/sub-gauge-adaptersmountain4don said:With a lot of discussion recently about the use of straight wall wads in tapered wall hulls, and tapered wall wads in straight wall hulls, I was wondering if a study had been performed about the actual differences in performance of the actual straight wall vs tapered wall wads in the trip down the barrel. My first thought would be that the larger diameter straight wall wads would seal better against the barrel and produce a higher velocity out the end of the barrel than the smaller diameter tapered wall wads. Or maybe it doesn't make any difference as both of them are flexible enough to expand to the barrel and maintain the pressure of the burning and expanding gasses behind them? And still stay centered in the barrel? :?:

"Shot Velocity- Yet another shocker regarding Sub-Gauge Adapters is shot Velocity. GaugeMate clocked speed improvements of more than 100 FPS with its gauge adapters. While some people will go to their grave denying this, some people also believed the earth was flat. The chronograph doesn't lie. We even had independent labs verify it. The velocity increases come from less friction on the wad as it travels down the barrel. Think of the wad as expanding to the barrel size of the gun after it leaves the adapter. The wad in essence overextends, thought the wad is still stable and still seals with the barrel. The reduction in drag is significant enough to attain speed increases of over 100 FPS in many sizes of GaugeMate adapters tested."

17,856 posts

·

Joined 2003

wildflights,

I couldn't agree more! I did some testing with Little Skeeters with 20 to 28 and 20 to .410 adapters. I know they aren't as long as GaugeMates, but it was interesting what the readings were between the 20 ga and the 28 ga in the same barrel. Wad condition was much better than expected too.

Now, running the .410 in the 20 ga barrel, whole different tin of tuna! LAAARRRGE variation in velocities shot to shot. Patterns you could through a cat through anywhere, and that at 25 yd. Wads that for all intents and purposes were inside out and completely sideways coming out the barrel. Not so with the 28 ga wads in the 20 ga barrel. The problem with the 'Skeeters was they were so thin that they expanded and the hulls stuck in them making it almost impossible to get them out. Performance was pretty good all things considered. Now in a 12 ga, I doubt it would have been so good.

Considering what Baker has done for years, literally making a 12 ga into a 10 ga barrel and having NO blow-by issues, I can't believe an AA wad in a Cheddite/Federal hull will make an iota's worth of difference in performance. Keep in mind, no mater which hull and wad combination you use, they all go down the same barrel. It's what happens at the instant of ignition that matters. Any hull expands to the confines of the chamber, even a straight wall hull with a tight fitting wad expands. So do the wads lips regardless of the dia, within reason of course. A 20 ga wad in a 12 ga hull is a different story. Even a 16 ga wad in a 12 ga hull just might surprise you as to how well it may work! Heck, I just may try that one of these days just to find out.

BP

I couldn't agree more! I did some testing with Little Skeeters with 20 to 28 and 20 to .410 adapters. I know they aren't as long as GaugeMates, but it was interesting what the readings were between the 20 ga and the 28 ga in the same barrel. Wad condition was much better than expected too.

Now, running the .410 in the 20 ga barrel, whole different tin of tuna! LAAARRRGE variation in velocities shot to shot. Patterns you could through a cat through anywhere, and that at 25 yd. Wads that for all intents and purposes were inside out and completely sideways coming out the barrel. Not so with the 28 ga wads in the 20 ga barrel. The problem with the 'Skeeters was they were so thin that they expanded and the hulls stuck in them making it almost impossible to get them out. Performance was pretty good all things considered. Now in a 12 ga, I doubt it would have been so good.

Considering what Baker has done for years, literally making a 12 ga into a 10 ga barrel and having NO blow-by issues, I can't believe an AA wad in a Cheddite/Federal hull will make an iota's worth of difference in performance. Keep in mind, no mater which hull and wad combination you use, they all go down the same barrel. It's what happens at the instant of ignition that matters. Any hull expands to the confines of the chamber, even a straight wall hull with a tight fitting wad expands. So do the wads lips regardless of the dia, within reason of course. A 20 ga wad in a 12 ga hull is a different story. Even a 16 ga wad in a 12 ga hull just might surprise you as to how well it may work! Heck, I just may try that one of these days just to find out.

BP

334 posts

·

Joined 2009

Burnt powder; I always thought that when you see the wad come out the shot was in front of it.

334 posts

·

Joined 2009

Burnt powder; I always thought that when you see the wad come out the shot was in front of it.

17,856 posts

·

Joined 2003

limpy100,

You point is what exactly?

You post implied to me that you are seeing muzzle flash, "3 foot flame", coming out of the barrel because the burning gas somehow got by the over powder lip of the over powder cup beating the shot and wad out of the barrel because of using a tapered hull wad in a straight wall hull? Is that not what you are referring to?

It's got nothing whatever to do with your last post of shot in front of the wad, in fact I've no idea how your last post is relevant to anything either your first post or mine mentioned. You seemed to say fire was the first thing out of a barrel or at least at the same time as the shot, using what you call the wrong wad.

I'm tossing the brown BS flag on that one too. You don't have a clue what you're talking about. For that matter, neither do I!

BP

You point is what exactly?

You post implied to me that you are seeing muzzle flash, "3 foot flame", coming out of the barrel because the burning gas somehow got by the over powder lip of the over powder cup beating the shot and wad out of the barrel because of using a tapered hull wad in a straight wall hull? Is that not what you are referring to?

It's got nothing whatever to do with your last post of shot in front of the wad, in fact I've no idea how your last post is relevant to anything either your first post or mine mentioned. You seemed to say fire was the first thing out of a barrel or at least at the same time as the shot, using what you call the wrong wad.

I'm tossing the brown BS flag on that one too. You don't have a clue what you're talking about. For that matter, neither do I!

BP

5,988 posts

·

Joined 2004

I think DLM, REPUBLICAN & BURN POWDER have it figured out as well as it can be analyzed. They have me convinced anyway. I think everybody agrees that a tight fitting wad is a good thing & a loose fitting wad & powder migration are bad things.The whole straight wall, tapered wall thing is based on the concept that straight wall wads are wider to fit the wider straight wall hulls but are they really? Look at the pics posted above. Some of the so called straight wall wads show more powder migration than the crooked wall wads. I have no doubt that some wads fit the hulls they say they will fit very well. Some do & some don't. I haven't measured any currently manufactured wads but the ones I measured a few years ago very often did not. Some of the wads supposedly for reifenhauser hulls had a big enough gap to drive a truck through. Obviously, if you are getting a lot of powder in the cushion section of your wad, you need to change something. I found that the WWAA12F114 wad had a bigger gas seal than other WWAA12 wads. One thing I like about WWAA wads is that they have a long, flexible skirt & rarely fail to seal well. Very light, sub gauge shot charges compound the problem of ignition. One thing I found with the 10 ga.. 2 oz. loads always went bang with authority. Drop the load to 1.25 oz. & unless you have a very good crimp & even with a faster powder like Unique, you have a receipt for a blooper.

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 4.5M

- members

- 165K

- Since

- 2000

A forum community dedicated to Shotgun owners and enthusiasts including the Remington, Beretta, and Mossberg shotguns brands. Come join the discussion about optics, hunting, gunsmithing, styles, reviews, accessories, classifieds, and more!